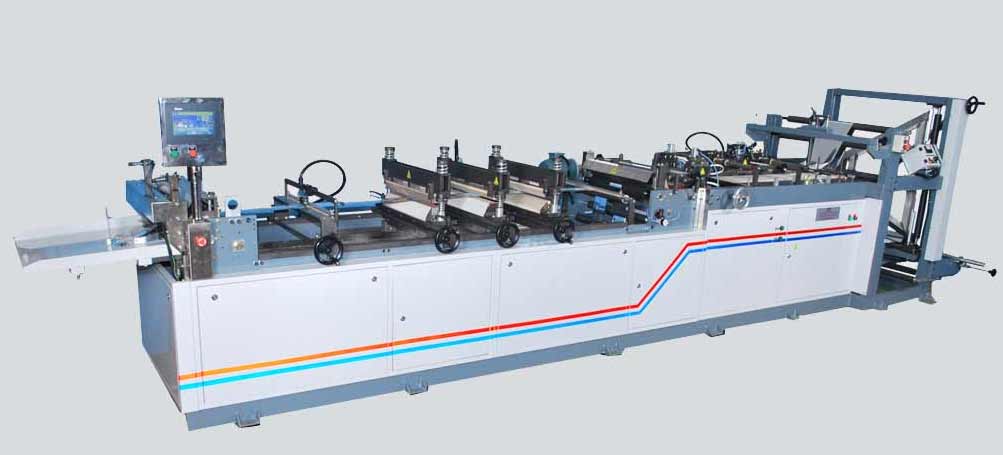

CENTER SEAL, SIDE SEAL AND THREE SIDE SEAL POUCH MAKING MACHINE

MODEL: MPM-CP240 S3

SPECIFICATION

FEATURES

ACCESSORIES

OPTIONAL

DESIGN

SPECIFICATION

| MINIMUM WIDTH | 60 mm |

| MAXIMUM WIDTH | 240 mm |

| MINIMUM LENGTH | 60 mm |

| MAXIMUM LENGTH | 500 mm |

| MAXIMUM SPEED | 220 pouches/min * |

| ROLL WEIGHT / DIAMETER | D – 600 mm (or) 80 Kg |

| MAX WEB WIDTH | 500 mm |

* DEPENDING ON THE SIZE & FILM THICKNESS

# ACCESSORIES SHOWN IN THE IMAGE IS NOT STANDARD ITEMS

COMPATIBLE MATERIALS: Plain or Printed, Multi Layer Laminated Film, BOPP Films

FEATURES

- MAIN DRAW ROLLER SERVO DRIVEN, CONTROLLED BY PLC.

- AC DRIVERS & SERVO DRIVER ARE SYNCHRONIZED

- SINGLE STATION UNWIND WITH MANUAL POWDER BRAKE.

- FILM CUT SENSOR FOR LOADING.

- CONTINUOUS MOTION CENTER SEALING & SIDE SEALING WITH AUTO OPEN CLOSE.

- TWO STAGE BOTTOM SEALING & ONE STATION COOLING.

- HIGH SPEED COLOUR MARK SENSOR.

- AUTO ERROR MESSAGE WITH MACHINE OFF.

- LOW TEMPERATURE PROTECTION.

- PRINT MARK MISS PROTECTION.

- SHOCKLESS STATIC DISCHARGER.

- OVERSPEED PROTECTION.

ACCESSORIES

- Forming sheet 3nos

- 8mm, 10 mm, 16mm & 20mm seal bars each 2nos

- Machine wiring diagram & tool kit

OPTIONAL

- ‘V’ Notch

- Hole punch

- ‘D’ Punch

- Perforation Sealer

- Auto Tension control brake

- Edge guide system

- Auto stacker

- UNIVERSAL FORMING UNIT (User friendly operation for center, side, three & quad seal)

# Without UNIVERSAL FORMING five side seal can not be produced #

DESIGN

- Single structure LASER CUT.

- Time for installing the machine after unloading is 3hrs.

- Wiring type PLUG & PLAY

View More