Call Us

+91 8056252363Email Us

itismpmmadhan@gmail.comPouch, Bags & E-Commerece Paper Bag Making Machine Manufacturer

- Home

- Machineries

- Standard Machines

- Stand Up, Zipper Lock Pouch making machine

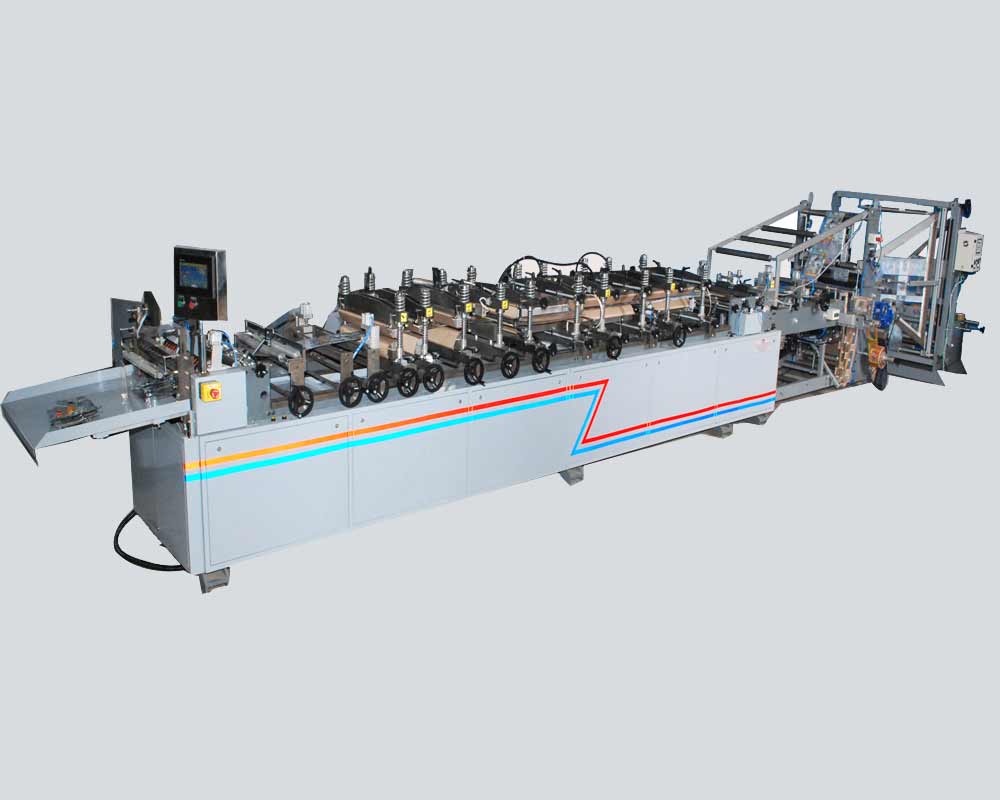

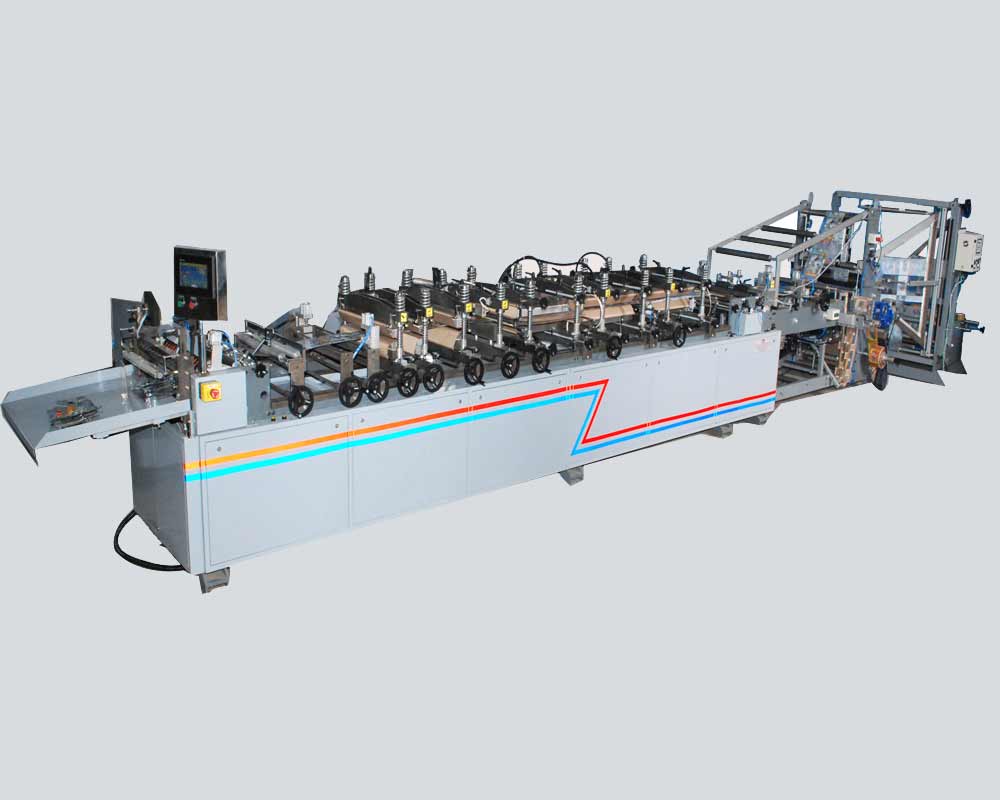

- MPM-CP240 S3

Specifications

TYPE OF POUCH & DESCRIPTIONS | POUCH SIZE FROM SINGLE WEB | |||

|---|---|---|---|---|

| SINGLE LINE | DOUBLE LINE | |||

| HEIGHT | WIDTH | HEIGHT | WIDTH | |

| SIDE SEAL & THREE SIDE SEAL POUCHES PLAIN (OR) ZIPPER _ Minimum | 120 | 80 | 100 | 80 |

| SIDE SEAL & THREE SIDE SEAL POUCHES PLAIN (OR) ZIPPER _ Maximum | 600 | 400# | 300 | 400# |

| STAND-UP POUCH PLAIN & ZIPPER _ Minimum | 120 | 80 | 100 | 80 |

| STAND-UP POUCH PLAIN & ZIPPER _ Maximum | 550 | 400 | 225 | 400 |

| QUAD SEAL (FIVE SIDE) POUCH _ Minimum | 120 | 100 | ||

| QUAD SEAL (FIVE SIDE) POUCH _ Maximum | 400# | 450 { Side gusset 60mm (Both Sides) } | ||

| DESCRIPTION | SPECIFICATION |

|---|---|

| MAIN ROLL MAXIMUM WEB WIDTH | 1200mm ( For Quad Seal 1000mm) |

| MAXIMUM SPEED | 180 cycles/min ** |

# 800mm with Skiping Mode for Three & Quad seal Pouches

** Depending on type of pouch, size and thickness of laminate.

*** Accessories shown in the image is not standard items.

- Single Web Unwind stand with Primary unwind draw roller assembly & Primary film buffer system.

- Roll End Detection Sensor.

- Auto Tension Control Powder Brake 5KG with load cell and Edge guide system.(Optional Multi Web).

- Folding Device with ’Y’ axis movement & Secondary unwind draw roller assembly with secondary film buffer system.

- Two Sets of Bottom Gusset Film Feeding System:

- Air Shaft, Unwind AC Motor, Folding Device and buffer Roller Assembly.

- Infeed Servo Draw Rollers

- Dia 12mm Standee punching Unit – 2 Sets, with ‘X’ &’Y’ axis movement & Bottom Gusset assembly with ’Y’ axis

- Two Sets of zipper sealing station with ‘X’ &’Y’ axis movement.

- Two Sets standee sealing & 850mm Inline Sealing (Linear to Film) Inter Changeable, ‘X’ &’Y’ axis movement

- Middle draw servo roller.

- Four Station Cross Sealing (Perpendicular to Film) with ‘X’ axis movement.

- High speed Colour Mark Sensor.

- Main Draw Servo Roller.

- Main Servo Motor Drive & Unwind motor AC Drives are synchronized.

- Touch Screen Display with Native Language.

- Shockless Static Discharger.

- Built-in counter with buzzer.

- Independent programmable timers for Punch and other optional attachment.

- Hole Punch and Optional Punching stations operated by Pneumatic cylinders

- Slitting and Automatic Trim removing. (Winder Type)

- Single structure LASER CUT machine.

- Time for installing the machine after unloading is 3 to 5 hrs.

- Wiring type PLUG & PLAY.

Product Videos

Checkout Other Machineries

Center, Side, Three & Quad seal pouch making machine

E-Commerce Paper Bag Making Machine

Stand Up, Zipper Lock Pouch making machine

Bottom Seal Bag Making Machine

Side Seal Bag Making Machine

Madhan Packaging Machineries

Contact us

Madhan Packaging Machineries

7, Balaji Nagar, Multi Industrial Nagar.

Gerugambakkam,Chennai 600 122.

Tamil Nadu, India

standard Machines

Eco-Friendly Machines

© 2024,Madhan Packagings Machineries, All Right Reserved.

Developed By Jayamwebsolutions